Haɗin Kan Labulen Gilashin Tsarin bangon bangon waje na Ƙirar Ƙirar Ƙirar Ƙirar Ƙira a Ƙasashen Waje

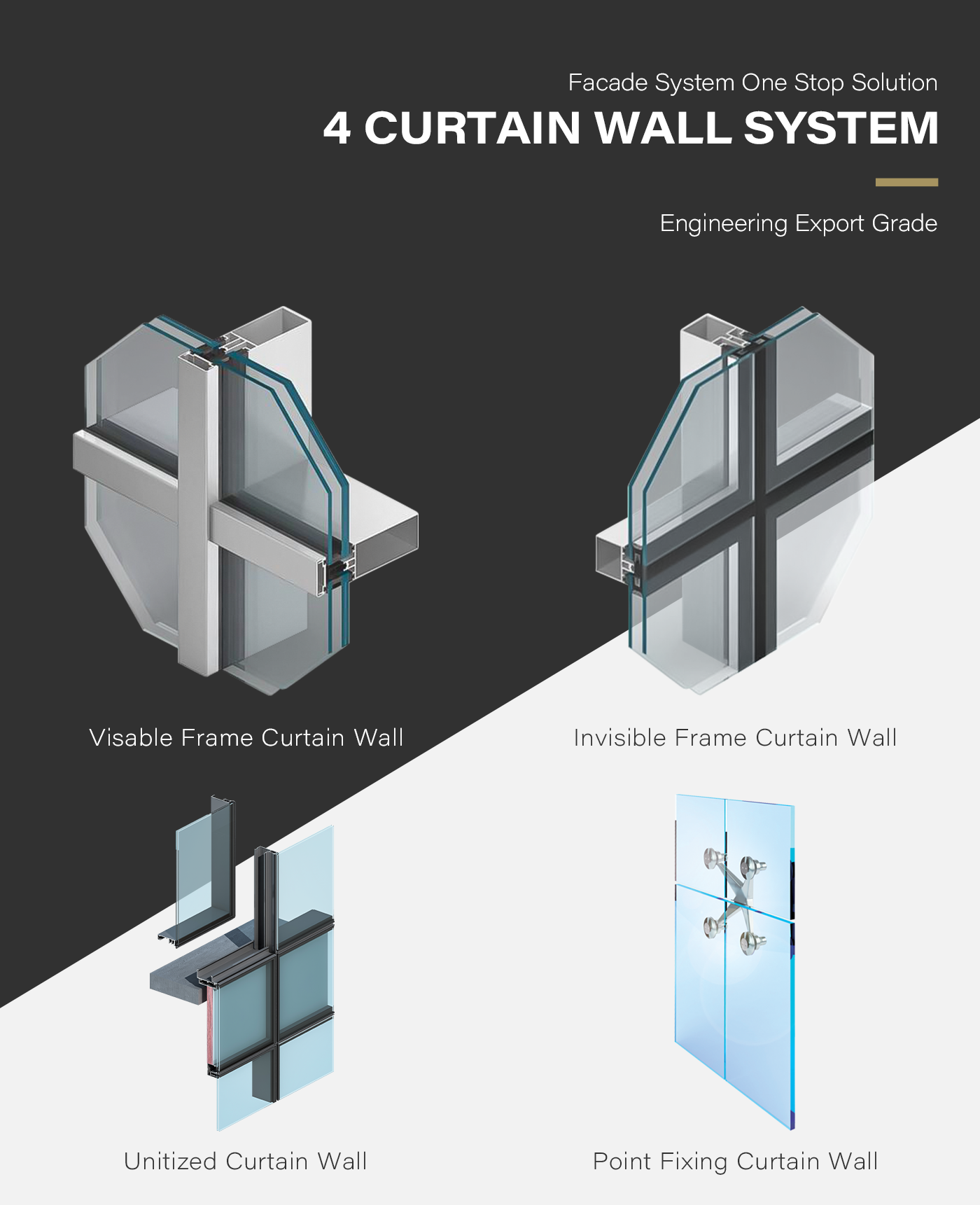

Halayen bangon labule mai haɗin kai

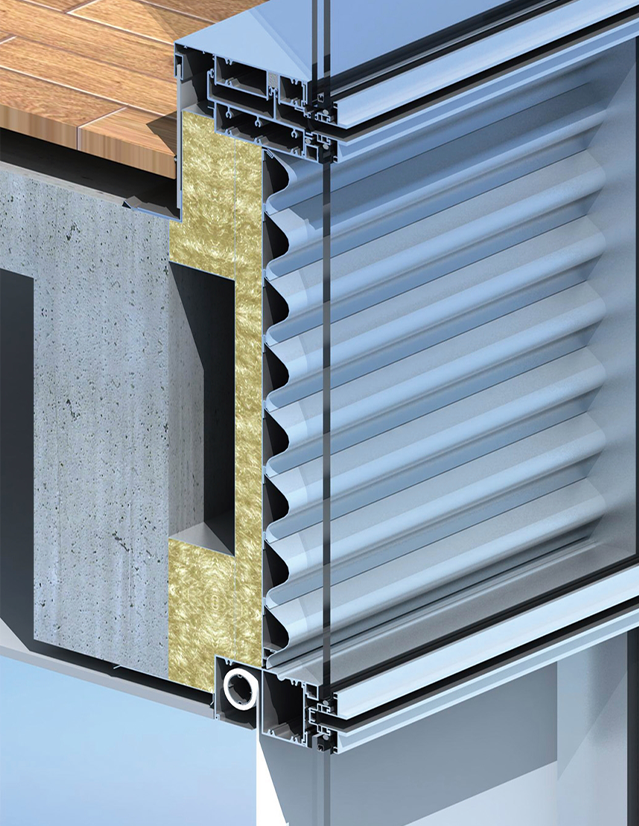

Babban abubuwan da ke haifar da karkatar da babban tsarin gine-ginen jama'a sune: kuskuren gini na ginin farar hula, rashin daidaituwa, kasancewar microseismic bayan amfani, nakasar girgizar ƙasa.An shigar da bangon labulen da aka haɗe ta cikin ramummuka tsakanin kowane farantin da ke kusa da shi kuma yana da kyakkyawan haɓakawa da ƙarfin lalacewa

Kowane farantin naúrar bangon labule gabaɗaya gabaɗaya ne, don haka matsugunin dangi na kowane ɓangaren naúrar yana da ƙanƙanta sosai, kuma ana iya tabbatar da amincin farantin bayan haɓakawa da sake saita nakasawa.

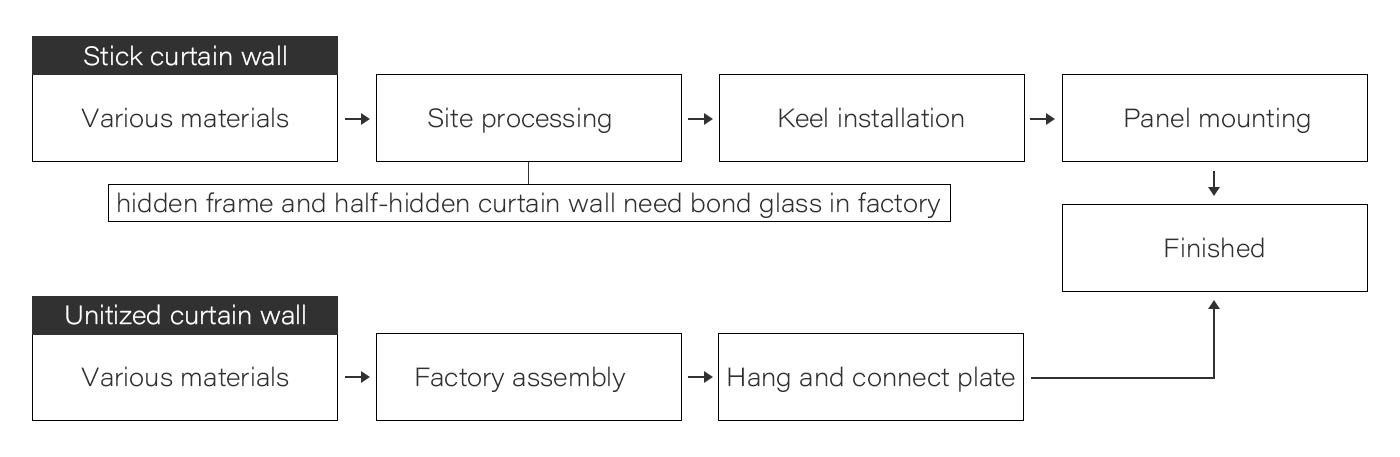

Tun da jikin naúrar ya taru a cikin masana'anta kuma ana iya shigar da shi kai tsaye bayan an kai shi zuwa wurin, ba tare da ɗaukar sarari da yawa akan rukunin yanar gizon ba kuma kawai yana da kusan kashi 30% na bangon labulen sanda, wanda ke guje wa tari na dogon lokaci. yadda ya kamata ya rage asarar adadin samfuran da aka kammala.

Halayen bangon labulen firam ɗin da aka fallasa, bangon bangon firam ɗin ɓoye, haɗin kan bangon labule rabin-boye.

| 01 | An kammala faranti na raka'a duk a cikin masana'antar bitar tare da daidaito mai girma. |

| 02 | Saurin shigarwa mai sauri, ɗan gajeren lokacin gini, mai sauƙin kare samfuran da aka gama. |

| 03 | Ana iya gina shi tare tare da babban tsarin gine-ginen gine-gine, wanda ke da amfani don rage duk lokacin ginin. |

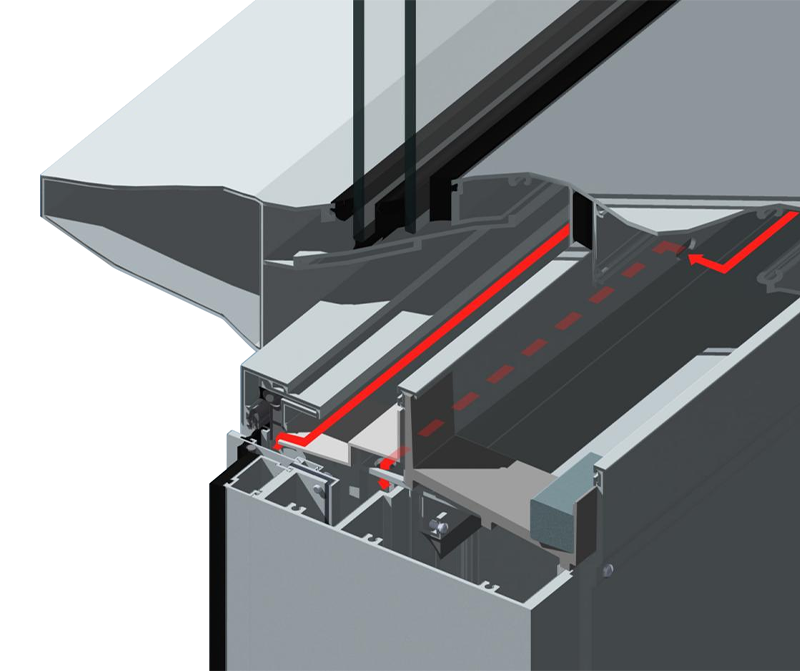

| 04 | Tsarin yana ɗaukar ka'idar ragewa mataki-mataki, kuma an saita tsarin magudanar ruwa a ciki, wanda ke da kyakkyawan aiki na hana zubar ruwan sama da shigar iska. |

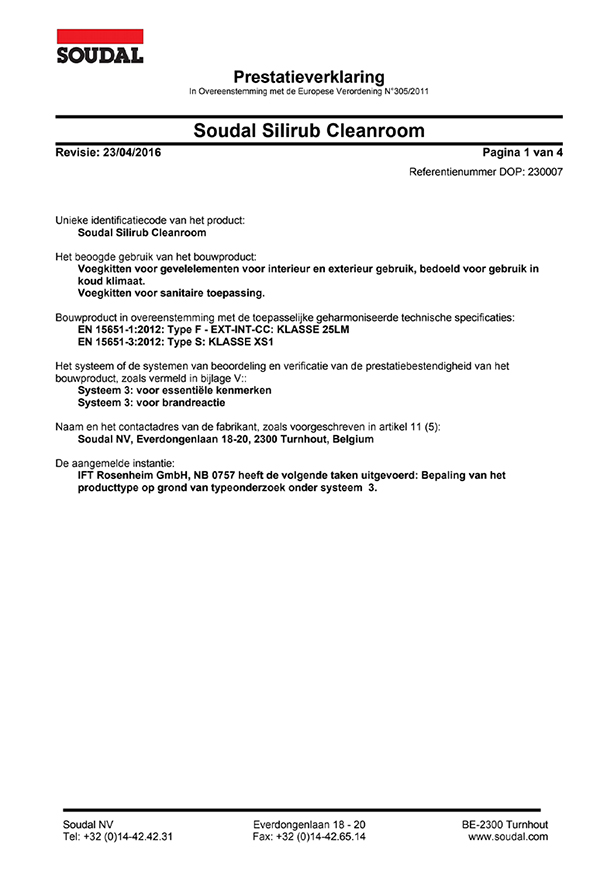

| 05 | Abubuwan haɗin faranti duk an rufe su da ɗigon roba na musamman da ke jure tsufa, wanda ke sa bangon labulen yana da aikin tsabtace kansa kuma saman bai ƙazantu ba. |

| 06 | Ana haɗe faranti ta hanyar grafting farantin, tare da ƙarfin girgizar ƙasa mai ƙarfi |

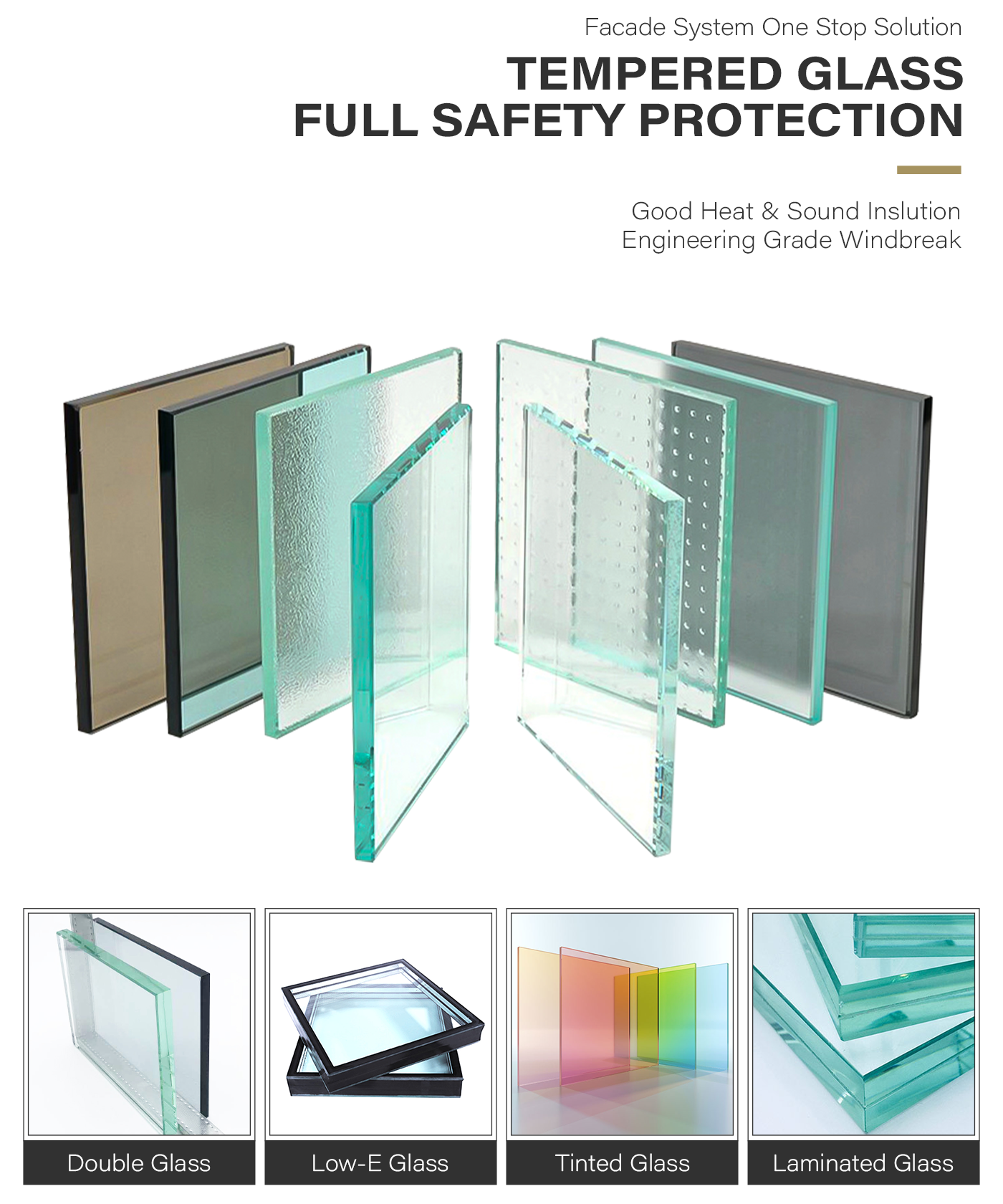

Raka'a masu zaman kansu bangon labulen gilashi

| Daidaitaccen samfuran | Ana iya shigar da shi kuma a kwance shi kyauta |

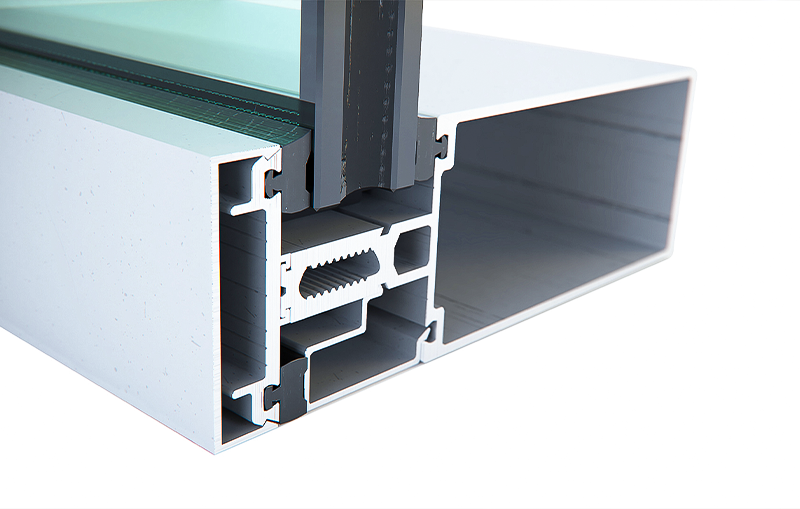

| Siffofin tsari | Gilashin yana fuskantar matsin iska ta farantin ƙugiya a ɓangarorin huɗu.Ƙirar ƙirar ƙirar ƙirar ta sa tsarin ya sami aikin kariya sau biyu |

| Tasirin gine-gine | Layin waje na gani a takaice ne kuma mai raye-raye, tare da kyawawa mai kyau |

| Aikace-aikace | Zai iya cimma babban farantin rabo, wanda ya dace da filin jirgin sama, zauren nuni da sauran babban gini |

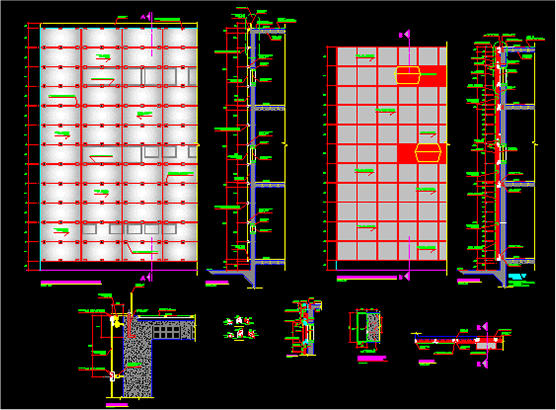

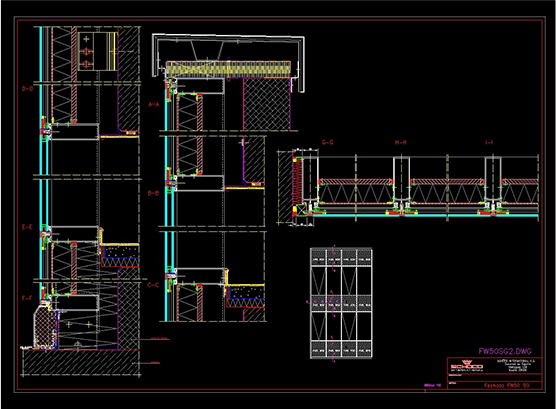

Ƙa'idar abun ciki

1.assemble kowane kashi (mullion, a kwance frame) a cikin naúrar bangaren frame a cikin masana'anta, da kuma shigar da labule bango panel (gilashi, aluminum farantin, dutse, da dai sauransu) a kan daidai matsayi na naúrar bangaren frame don samar da element composites.

2.Transport da bangaren taro zuwa wurin da kuma gyara kai tsaye a kan babban tsarin ta hoisting.

3.Ana shigar da firam na sama da na ƙasa (firam ɗin hagu da dama) na kowane ɓangaren naúrar don samar da sandar haɗin gwiwa da kammala haɗin gwiwa tsakanin sassan naúrar, a ƙarshe ya zama bangon labule gabaɗaya.

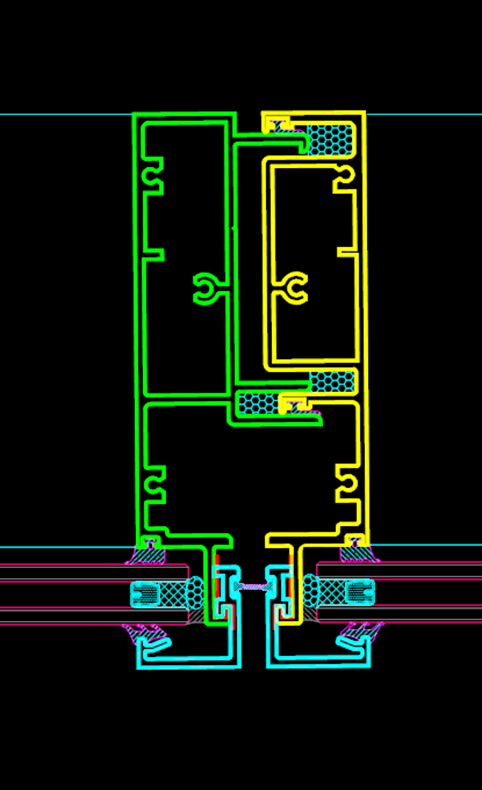

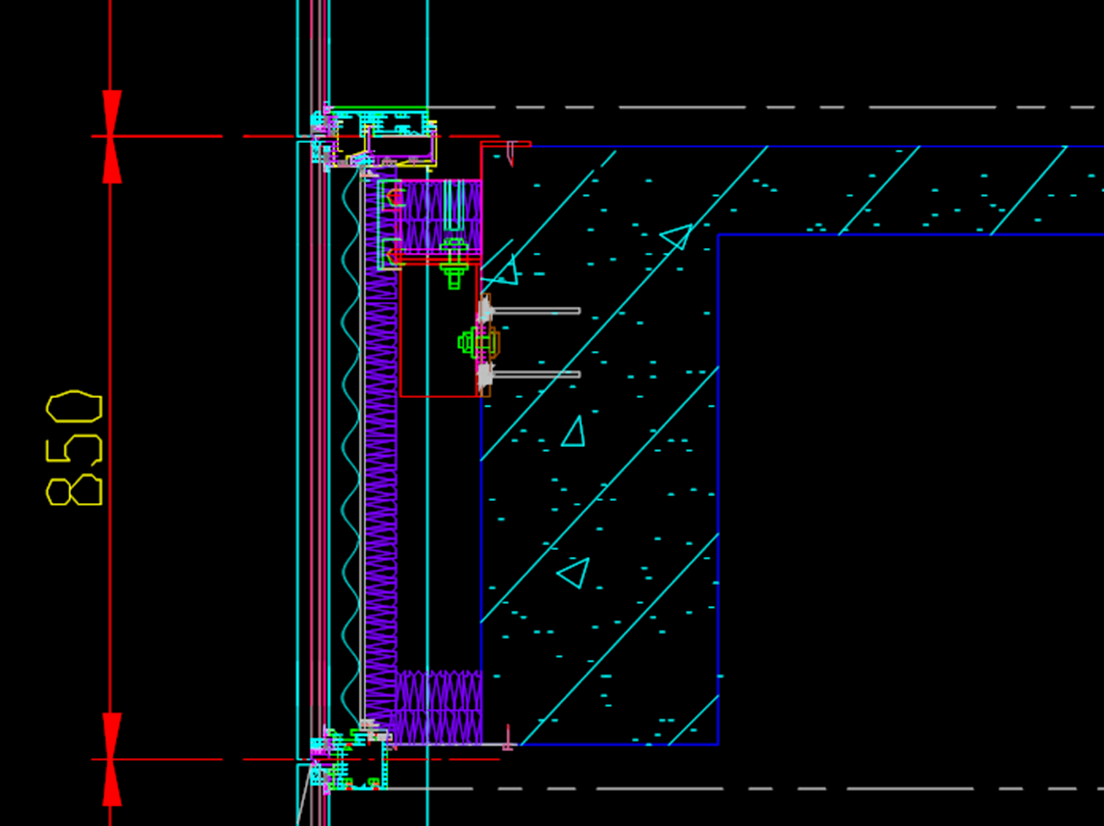

Tsare-tsare da ginshiƙi guda ɗaya na bangon bangon labule

Haɗin bangon labule

Shigar bangon labule

Haɗin bangon labule

Shigar bangon labule

Mai hana ruwa aiki

Hanyar magudanar ruwa

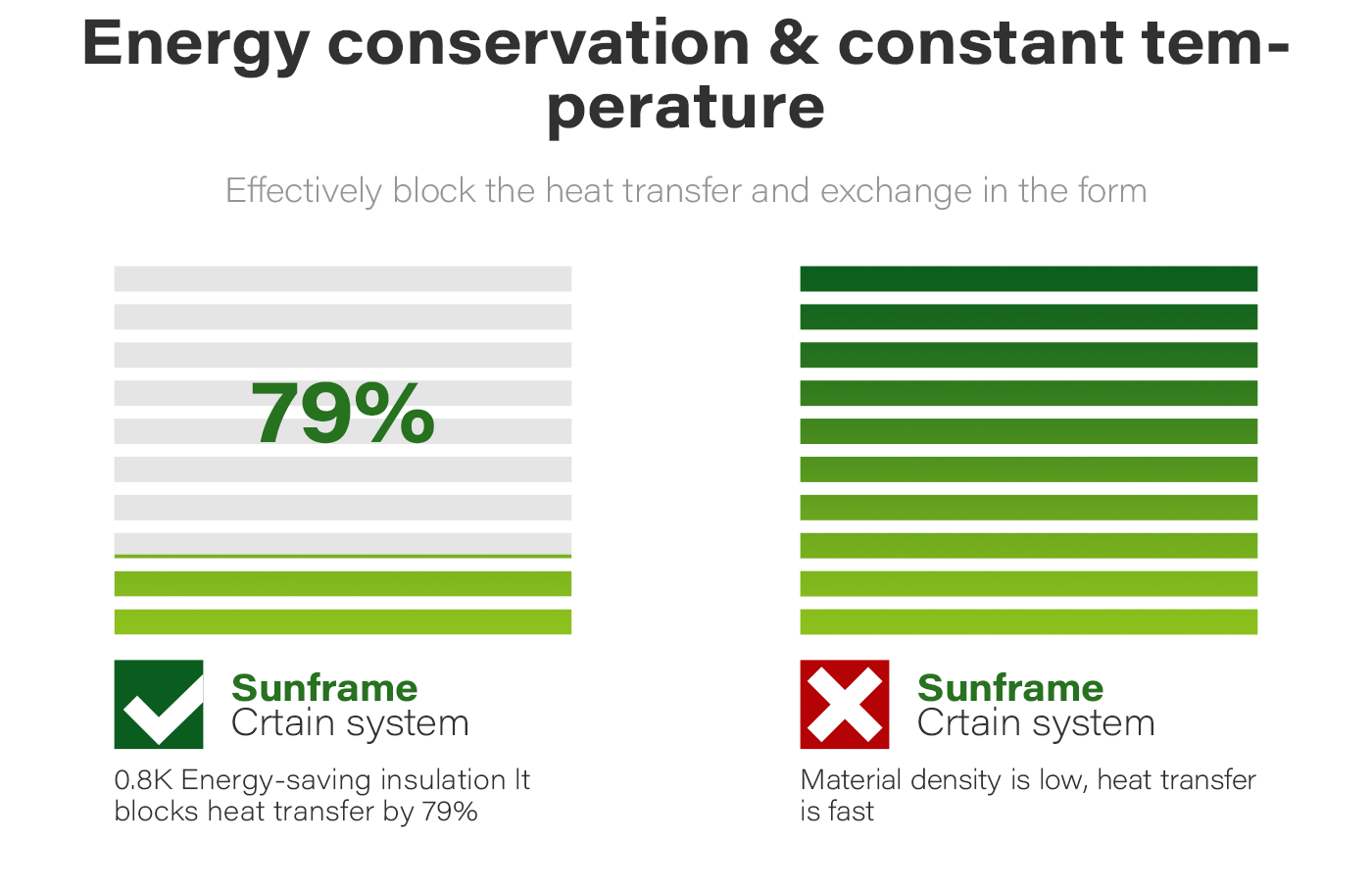

*Haɗin bangon labule yana ɗaukar "ka'idar isobaric", aikin hana ruwa yana da kyau

Zane mai rufi na bangon labule guda ɗaya

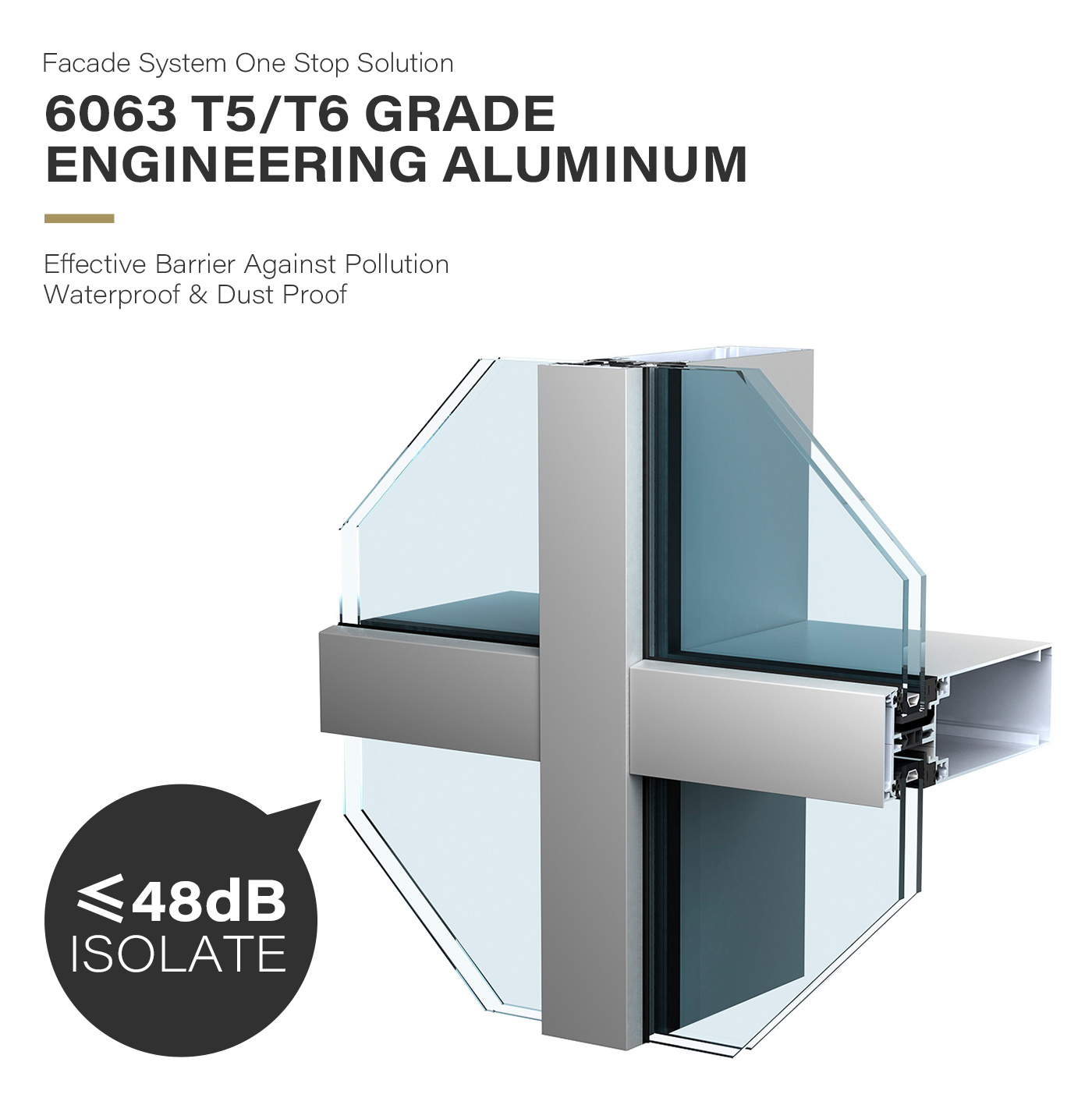

Gwajin bangon labule da gilashi

bangon labule tare da buƙatun aikin haske, ƙimar rage watsawa bai kamata ya zama ƙasa da 0.45 ba.bangon labule tare da buƙatun wariyar launin launi, ƙimar hangen nesansa bai kamata ya zama ƙasa da Ra80 ba

Bangon labule zai iya tallafawa nauyin kansa da nauyin kayan haɗi daban-daban a cikin zane, kuma za'a iya dogara da shi zuwa babban tsari.

Matsakaicin jujjuyawar memba a kwance a cikin tazara a duka ƙarshen panel guda ɗaya a ƙarƙashin madaidaicin mataccen nauyi bai kamata ya wuce 1/500 na tazara a ƙarshen panel ɗin ba, kuma kada ya wuce 3mm

Gilashin bangon labule yakamata a sarrafa shi ta tsoma mai zafi.Maganin zafi na biyu, jiyya mai zafi, jiyya na fashewa, "bayan jiyya na iya zama ƙasa da 1/1000 na adadin fashewar kai" ana amfani da su a aikin injiniya.

Marufi & jigilar kaya

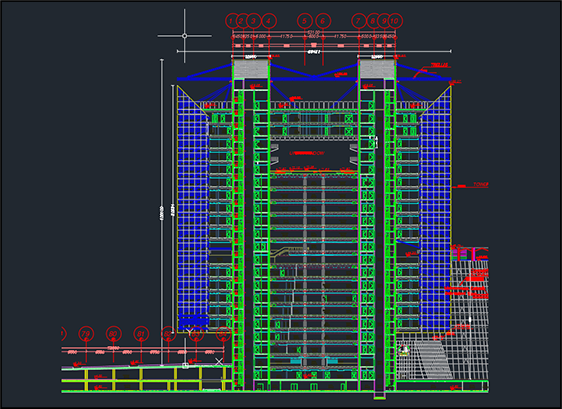

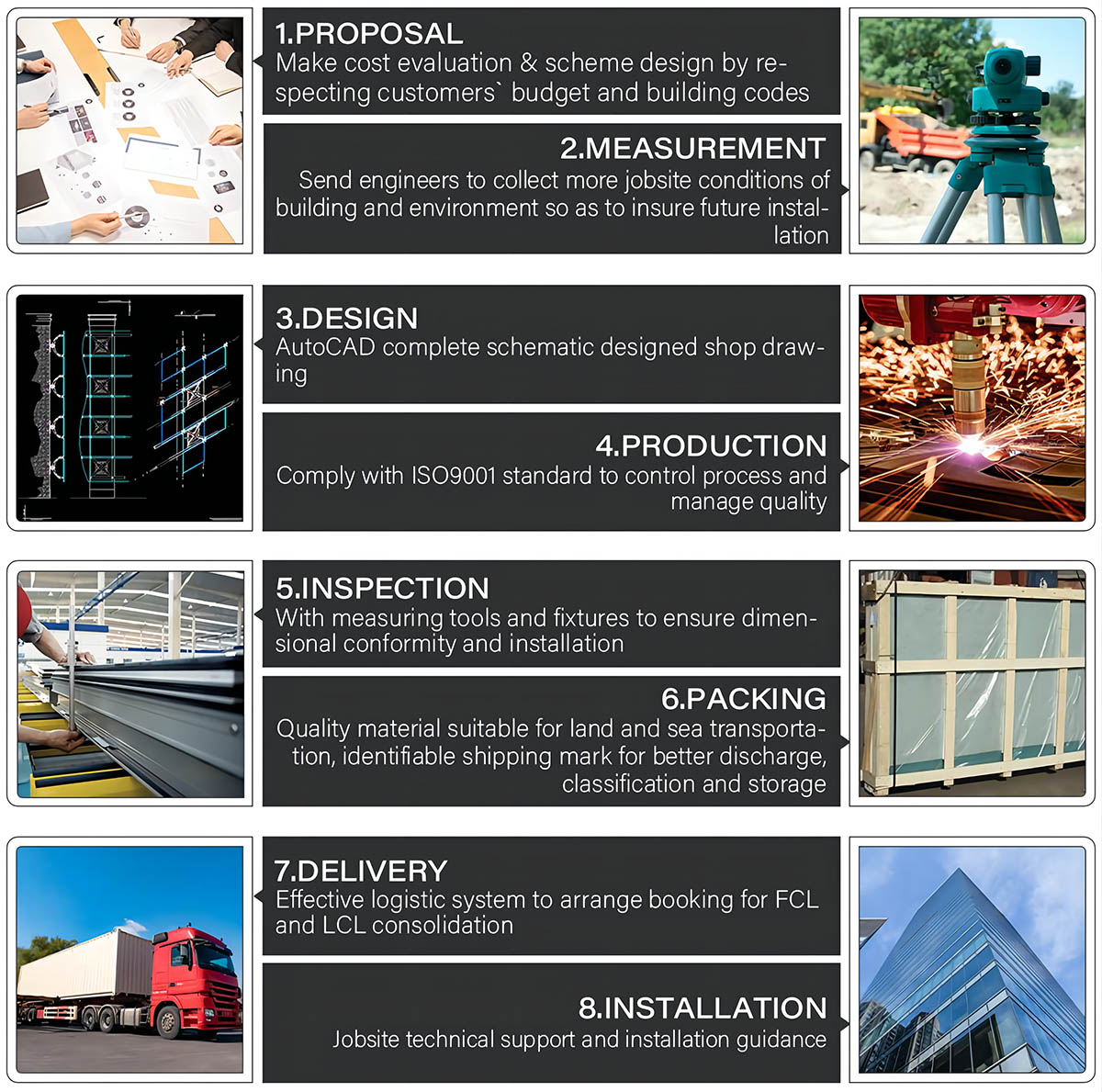

Zane Na Musamman Kyauta

Mun tsara hadaddun gine-ginen masana'antu don abokan ciniki ta amfani da AutoCAD, PKPM, MTS, 3D3S, Tarch, Tekla Structures (Xsteel) da dai sauransu.

Tsarin keɓancewa

Bayanin Bita na Production

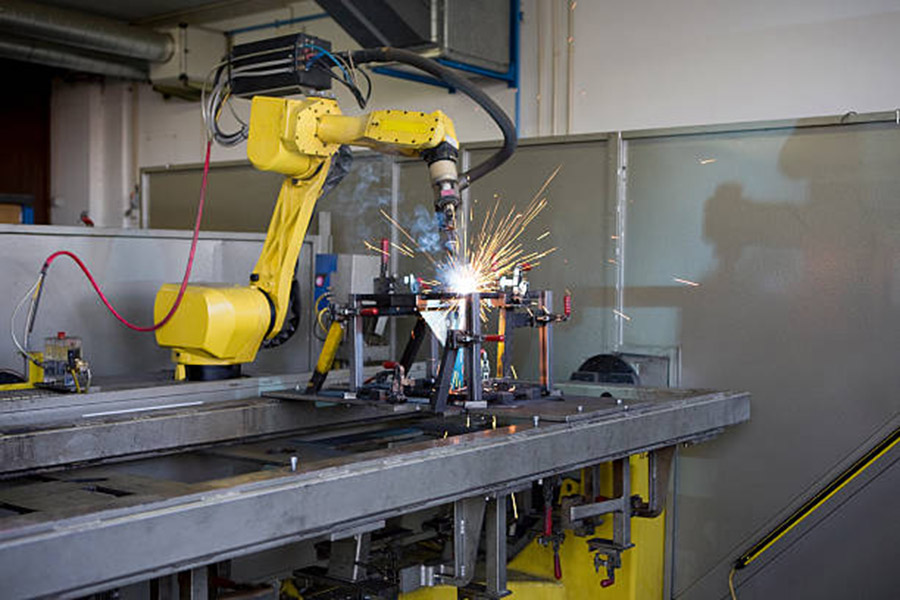

Iron Workshop

Raw Material Zone 1

Aluminum alloy workshop

Raw Material Zone 2

Injin walda na robotic da aka sanya a cikin sabon masana'anta.

Wurin fesa atomatik

Injin yankan da yawa

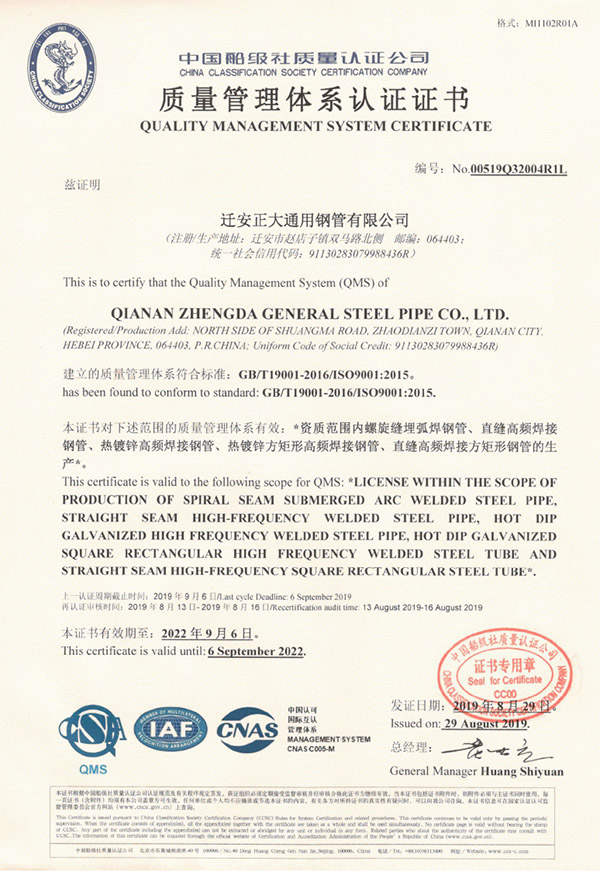

Hukumar tabbatarwa

Kamfanin haɗin gwiwa

FAQ

1.What's your masana'antu lokacin?

Kwanaki 38-45 ya dogara da biyan kuɗin da aka karɓa da kuma sanya hannu kan zanen shagon

2. Menene ya bambanta samfuran ku da sauran masu kaya?

Madaidaicin inganci mai inganci da farashi mai fa'ida sosai gami da tallace-tallacen ƙwararru da sabis na injiniyan shigarwa.

3. Menene tabbacin ingancin da kuka bayar kuma ta yaya kuke sarrafa inganci?

Ƙaddamar da hanya don bincika samfurori a duk matakai na tsarin masana'antu - albarkatun kasa, a cikin kayan aiki, ingantattun kayan ko gwadawa, kayan da aka gama, da dai sauransu.

4. Ta yaya ake samun ingantaccen zance?

Idan za ku iya samar da bayanan aikin masu zuwa, za mu iya ba ku da ingantaccen zance.

Lambar ƙira / ƙirar ƙira

Matsayin ginshiƙi

Matsakaicin saurin iska

Seismic lodi

Matsakaicin gudun dusar ƙanƙara

Matsakaicin ruwan sama