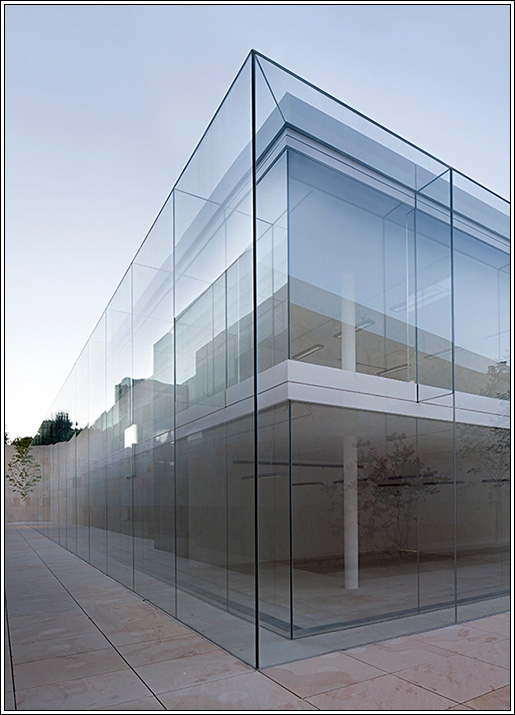

Cikakken Labulen Gilashin Tsarin bangon Gilashin Fushin Gilashin Facade Gilashin Sinanci

Cikakken tsarin bangon labulen gilashi

Akwai nau'i biyu don cikakken tsarin facade na gilashi, ɗayan yana tare da tsarin gilashin ribbed, ɗayan kuma ba tare da gilashin ribbed ba.

Gilashin Ribbed: Don ƙarfafa taurin gilashin gilashi, wajibi ne a yi amfani da gilashin tsiri a matsayin haƙarƙarin ƙarfafawa a wani nisa, wanda aka sani da gilashin ribbed.

| Matsakaicin tsayin cikakken facade gilashin | |||

| Kaurin gilashi (mm) | 10/12 | 15 | 19 |

| Matsakaicin tsayi (m) | 4 | 5 | 6 |

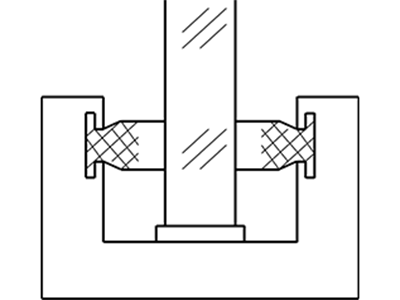

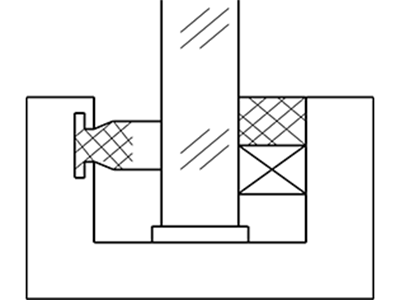

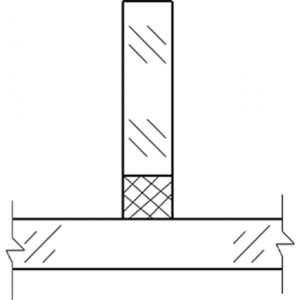

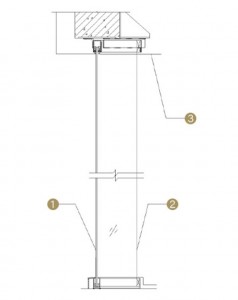

Nau'in da aka ɗora saman ƙasa cikakken facade na gilashi

Ma'anar:Lokacin da tsayin bangon labule ya yi ƙasa, ana shigar da gilashin saman da gilashin haƙarƙari tare da inlaying, kuma gilashin yana daidaitawa a cikin rami na ƙasa, kuma an ware wani wuri tsakanin saman saman katako na sama da gilashin. , don haka gilashin yana da dakin fadadawa da lalacewa.

Amfani:Tsari mai sauƙi, ƙarancin farashi, galibi ya dogara da ƙafar ƙafa don ɗaukar nauyi

Rauni:Gilashin yana da sauƙi don lanƙwasa da lalacewa a ƙarƙashin nauyin nauyin kansa, yana haifar da ɓarna na hoto na gani.

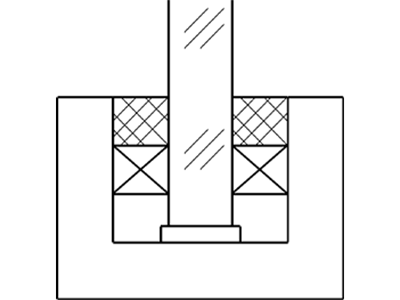

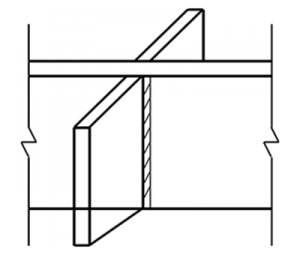

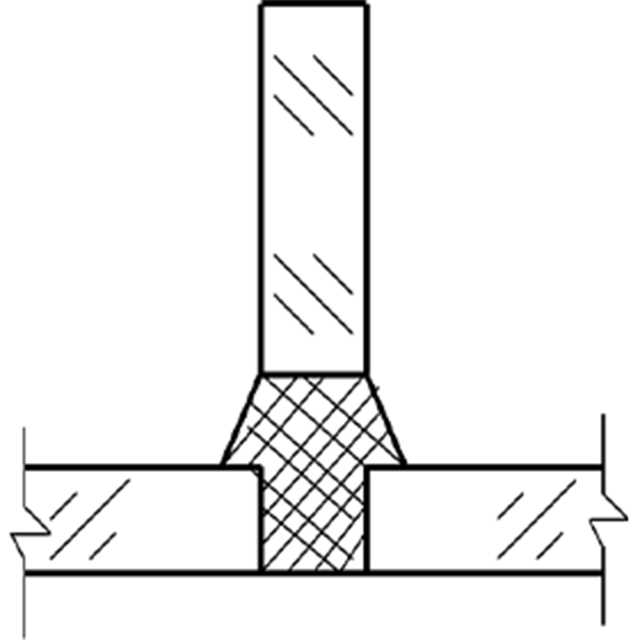

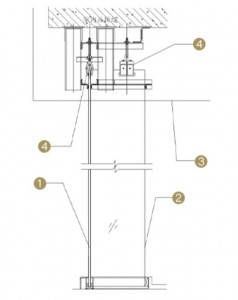

Nau'in rataye cikakken facade gilashin

Ma'anar:Lokacin da bangon labule ya yi tsayi, don hana gilashin dagewa da lalacewa a ƙarƙashin nauyin nauyinsa, an saita kayan ƙarfe na musamman a ƙarshen bangon labule, kuma an rataye babban gilashin don samar da gilashin ci gaba. bangon labule ba tare da nakasawa ba.Akwai sarari mai sassauƙa tsakanin gilashin da kasan ramin shigar.

Amfani:Zai iya kawar da jujjuyawar gilashin da ya haifar da ingancinsa kuma ya haifar da kyakkyawan sakamako, m da aminci.Ya dogara ne akan kayan aikin ƙarfe don ɗaukar nauyi.

Rauni:Tsarin yana da ɗan rikitarwa kuma yana da tsada sosai

Cikakken tsarin bangon labulen gilashi

Akwai nau'i biyu don cikakken tsarin facade na gilashi, ɗayan yana tare da tsarin gilashin ribbed, ɗayan kuma ba tare da gilashin ribbed ba.

Gilashin Ribbed: Don ƙarfafa taurin gilashin gilashi, wajibi ne a yi amfani da gilashin tsiri a matsayin haƙarƙarin ƙarfafawa a wani nisa, wanda aka sani da gilashin ribbed.

| Babu ribbed gilashin cikakken gilashin bangon labule | |

| Tsarin kumburi | Gilashin kafaffen hanyar shigarwa |

| Hanyar da aka saba amfani da ita ita ce saka ƙarshen babban gilashin cikin firam ɗin ƙarfe kuma a gyara shi da silin siliki | Akwai nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i) nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'in iska). |

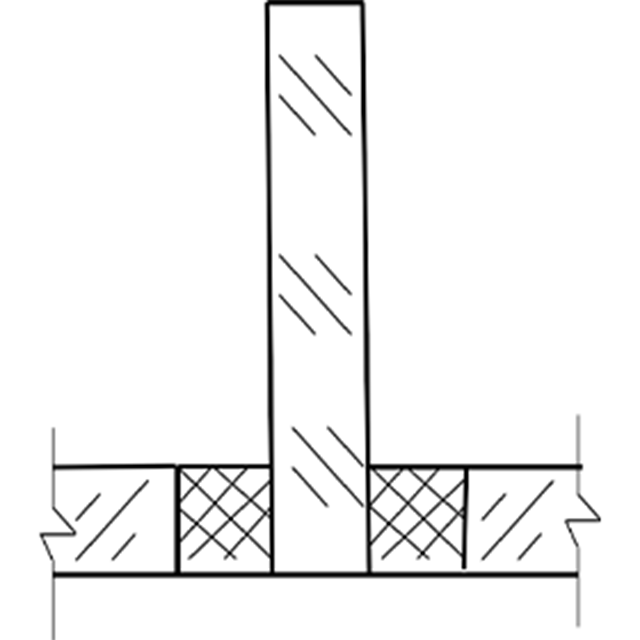

Bushewar nau'in taro

Lokacin shigar da gilashin, yi amfani da ɗigon hatimi (kamar igiyoyin rufewa na roba) don gyarawa

Taron nau'in rigar

Bayan shigar da gilashin a cikin ramin, yi amfani da sealant (misali silicone sealant) cika rata tsakanin gilashin da bangon tanki don gyarawa.

Hadawa taro

Busassun nau'in nau'in nau'in nau'in rigar suna haɗuwa a lokaci guda.Da farko gyara tsiri mai rufewa a gefe ɗaya, saka shi a cikin gilashin, sannan a ƙarshe gyara shi a gefe guda tare da silin siliki.

Lura:aikin rufewa na taron nau'in rigar ya fi na busassun nau'in taro, kuma rayuwar sabis na silicone sealant ya fi tsayi fiye da na tsiri na roba.

| Gilashin ribbed cikakken gilashin bangon labulen | |

| Intersecting surface tsarin na ribbed gilashi | |

| An shirya jagorancin saman gilashin haƙarƙari bisa ga wuri da aikin ginin, da bukatun fasaha.Yawanci akwai nau'ikan tsari guda uku game da haɗin gwiwa na gilashin fuska da gilashin ribbed: ribbed sau biyu, ribbed Single, Ta ribbed. |

Bushewar nau'in taro

Gilashin ribbed a bangarorin biyu, dace da bangon ciki na tsakiya

Taron nau'in rigar

Gilashin ribbed a gefe ɗaya, dace da bango na waje

Hadawa taro

Gilashin ribbed ta cikin gilashin saman, wanda ya dace da bangon labule mai girma.

| Intersecting surface jiyya na ribbed gilashin | |

| Gilashin fuska da gilashin ribbed ana haɗa su ta hanyar siliki na tsari mai haske, kuma jiyya na tsaka-tsaki na gilashin ribbed shine kamar haka: Nau'in Rear, nau'in nau'in kabu, Nau'in Flush, Nau'in Protruding. |

Nau'in baya

Haƙarƙarin gilashin yana a bayan gilashin fuskar, an ɗaure shi da gilashin fuska tare da mannen tsari gaba ɗaya.

Nau'in ruwa

Haƙarƙarin gilashin yana tsakanin gilashin fuska biyu, gefe ɗaya na haƙarƙarin yana manne da saman gilashin fuska, kuma ana amfani da mannen tsarin tsakanin haƙarƙarin da gilashin fuska biyu.Za a sami ɓarnawar chromatic a cikin hangen nesa saboda kauri daban-daban na watsawa ta gefe

Nau'in kabu mai hawa

Haƙarƙarin gilashin yana wurin haɗin gwiwar gilashin fuska biyu, kuma an haɗa guda uku na gilashi tare da manne tsarin.

Nau'in fitowa

Haƙarƙarin gilashin yana tsakanin gilashin fuska biyu, bangarorin biyu suna fitowa saman gilashin fuska, hakarkarin da gilashin fuskar an rufe su da mannen tsari.

Gyaran gilashin ribbed cikakken gilashin facade

Gilashin ribbed cikakken gilashin bangon labulen

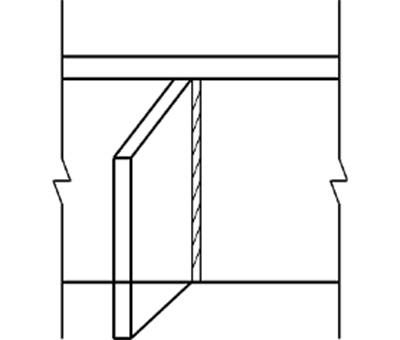

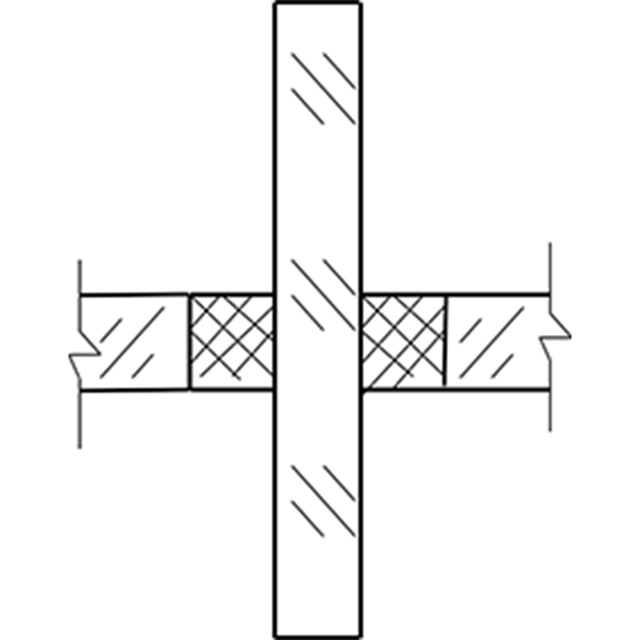

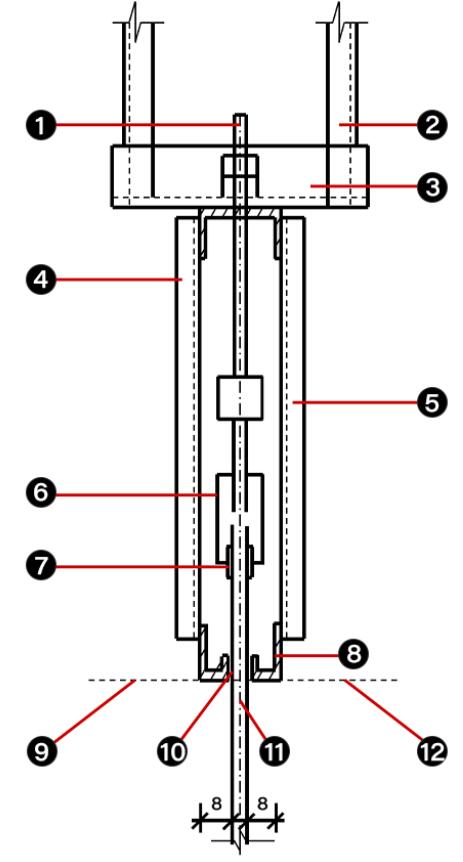

Nau'in rataye cikakken bangon labulen gilashi

Ƙofar kwance na bangon labulen gilashin-ribbed

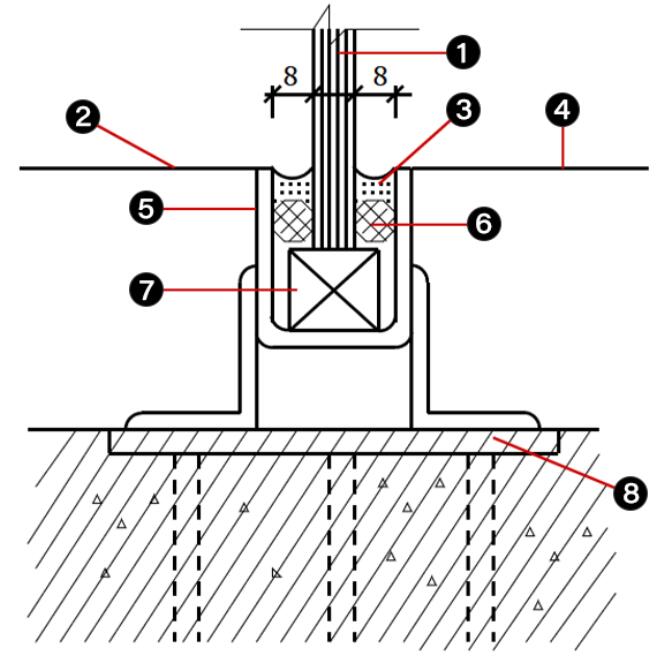

1. Gilashin zafi;2. Haƙarƙari mai zafi;3. Bakin karfe rataye tsarin matsawa;

4. Layin rufin cikin gida;5. Gilashin ginin manne

1.Hanging nau'in cikakken bangon labulen gilashi

Tsarin bangon labulen gilashin rataye ya ƙunshi sassa uku:

1.Upper nauyin rataye tsarin rataye: mai rataye karfe, katako na karfe, rataye mai rataye, madaidaicin rataye na doki, rataye tagulla, shirin karfe na ciki da na waje, cikawa da kayan rufewa, yanayin siliki na siliki.

Tsarin gilashin 2.Middle: gilashin gilashi;Gilashin ribbed farantin, silicone structural sealant.

3.Lower tsarin firam: karfe karfe, neoprene roba kushin, kumfa cika abu, weather-resistant sealant.

1.Bolt shigarwa;2. madaidaicin rataye na teel;

3. Karfe katako;4.External karfe clip;

5.Clip karfe na ciki;6.Sling;

7.Suspension clamp farantin;8.3mm SS tashar tashar karfe profile;

9. Ƙarshen waje;10.Silicone sealant;gilashin 11.19 mm;

12.Cikin rufi;

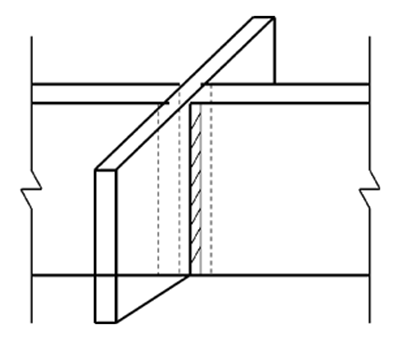

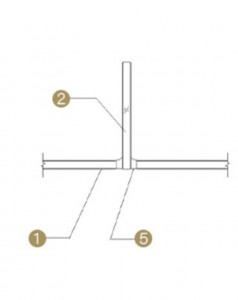

Zane na kumburin sama na nau'in rataye cikakken bangon labulen gilashi

Tsarin kumburin firam

gilashin 1.19 mm;

2. Ƙarshen waje;

3.Silicone sealant;

4.Interior surface;

5.3mm SS tashar karfe profile;

6.Kumfa cika kayan;

7.Neoprene spacer;

8. Abubuwan da aka haɗa;

1.The rata tsakanin kewaye rufaffiyar tsagi bango da gilashin panel ko gilashin hakarkarin kada ya zama kasa da 8mm, da rata tsakanin ƙananan ƙarshen rataye gilashin da kasa na ƙananan tsagi ya kamata saduwa da bukatun gilashi elongation nakasawa. .Gilashin da kasan ramin ƙananan ya kamata a goyan baya ko cika da kushin roba kuma tsawon kushin kada ya zama ƙasa da 100mm, kauri ba ƙasa da 10mm ba, Ya kamata a rufe shi da silinda ginin silicone tsakanin bangon tantanin halitta. da gilashin.

2.Babban bangon bangon labulen gilashin cikakke ba zai kasance cikin hulɗar kai tsaye tare da wasu kayan aiki masu ƙarfi ba.Rata tsakanin farantin farantin karfe da farfajiyar kayan ado ko tsarin tsarin bai kamata ya zama ƙasa da 8mm ba, kuma an rufe shi da sealant.

2.The babba hali rataye tsarin

1. Karfe mai rataye da katako

Yafi zabi tsarin karfe, gilashin bangarori da gilashin hakarkarinsa da sauran aka gyara nasu taro load da iska lodi dogara canjawa wuri zuwa babban tsarin.

2.Rataye sandar, dawaki rataye kayan aiki da rataye clip jan karfe

Dangane da girman lodin dakatarwa, sandar rataye da kayan aikin rataye sun kasu zuwa ma'auni na yau da kullun da nau'in nauyi

| Zaɓin ɗagawa mai ɗagawa da tebur nunin tsayin sarari da ake buƙata | ||

| Jure ingancin gilashin rataye (KG) | Nau'in kayan aikin rataye | Tsayin ginin da ake buƙata (MM) |

| Wg <450 | Daidaitawa | :450 |

| 450≤Wg≤1200 | Nau'in nauyi | · 550 |

3.Cikin ƙarfe na ciki da na waje

Ƙarfe na ciki da na waje sune tsarin rufewa na gefen saman bangon labulen gilashi bayan an dakatar da gilashin, yana da kyau a zabi bakin karfe.

Aiki

An sanya gilashin a cikin ɓangaren sama, ta yadda gilashin fuska za a iya watsa shi daidai da gilashin haƙarƙari da rataye na karfe bayan ɗaukar nauyin iska.A lokaci guda kuma, shi ne mahadar da kuma rufe matsayi na cikin gida da aka dakatar da rufi da kayan ado na waje da kuma cikakken bangon labulen gilashi.

Shigarwa

Don ɗaga gilashin fuska a wurin, gyara faifan ƙarfe na ciki da farko, sannan gyara faifan ƙarfe na waje tare da kullin shigarwa bayan an dakatar da gilashin.

3.Material ƙayyadaddun bayanai da aikin fasaha

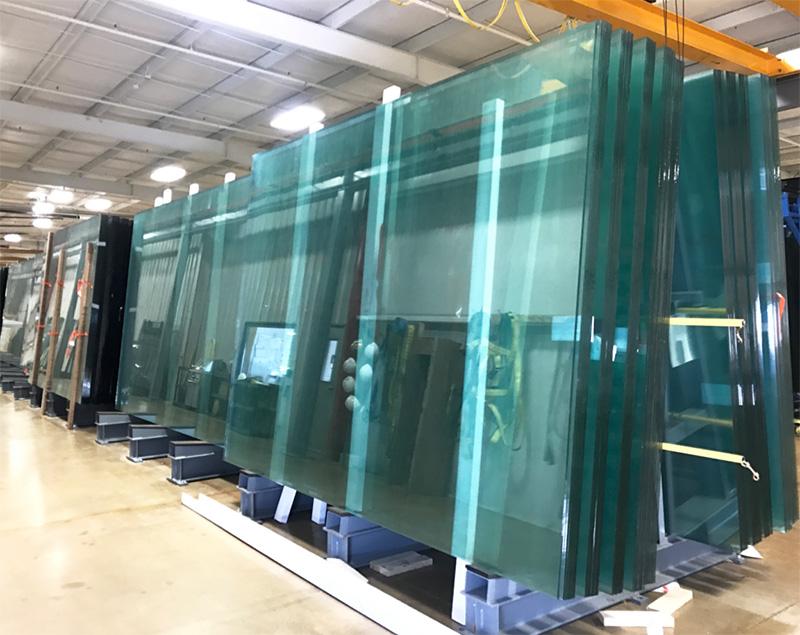

Gilashin

1. Nau'i:

gilashin zafi, gilashin da aka lanƙwasa da dai sauransu.

2. Kauri:

ta hanyar ƙira da lissafi don ƙayyade, mafi yawan amfani da ita shine 12/19mm.

3. Magani:

ya kamata a goge shi kuma ya hana ƙananan raguwa bayan yankan gilashi, rata yana da sauƙi don samar da sakamakon damuwa a cikin gilashin gilashi.

1. Ƙarfin Ƙarfi:

Ana amfani da mannen tsarin siliki tsakanin gilashin fuska da gilashin ribbed, nisa da kauri na haɗin gwiwa ya kamata a duba ta ƙarfi.

2. Matsala:

Ya kamata a yi amfani da siliki mai tsaka-tsaki tsakanin gilashin da firam ɗin ƙarfe da lankwasa.

Silicone tsarin sealant

Karfe frame

A cikin rataye nau'in cikakken aikin bangon labulen gilashi, ƙirar ƙarfe da aka binne a ƙasa ko a bangon yana da kyau a yi amfani da 3mm lokacin farin ciki bakin karfe tsagi karfe firam.

Shigarwa da tsarin gina ginin bangon labulen rataye

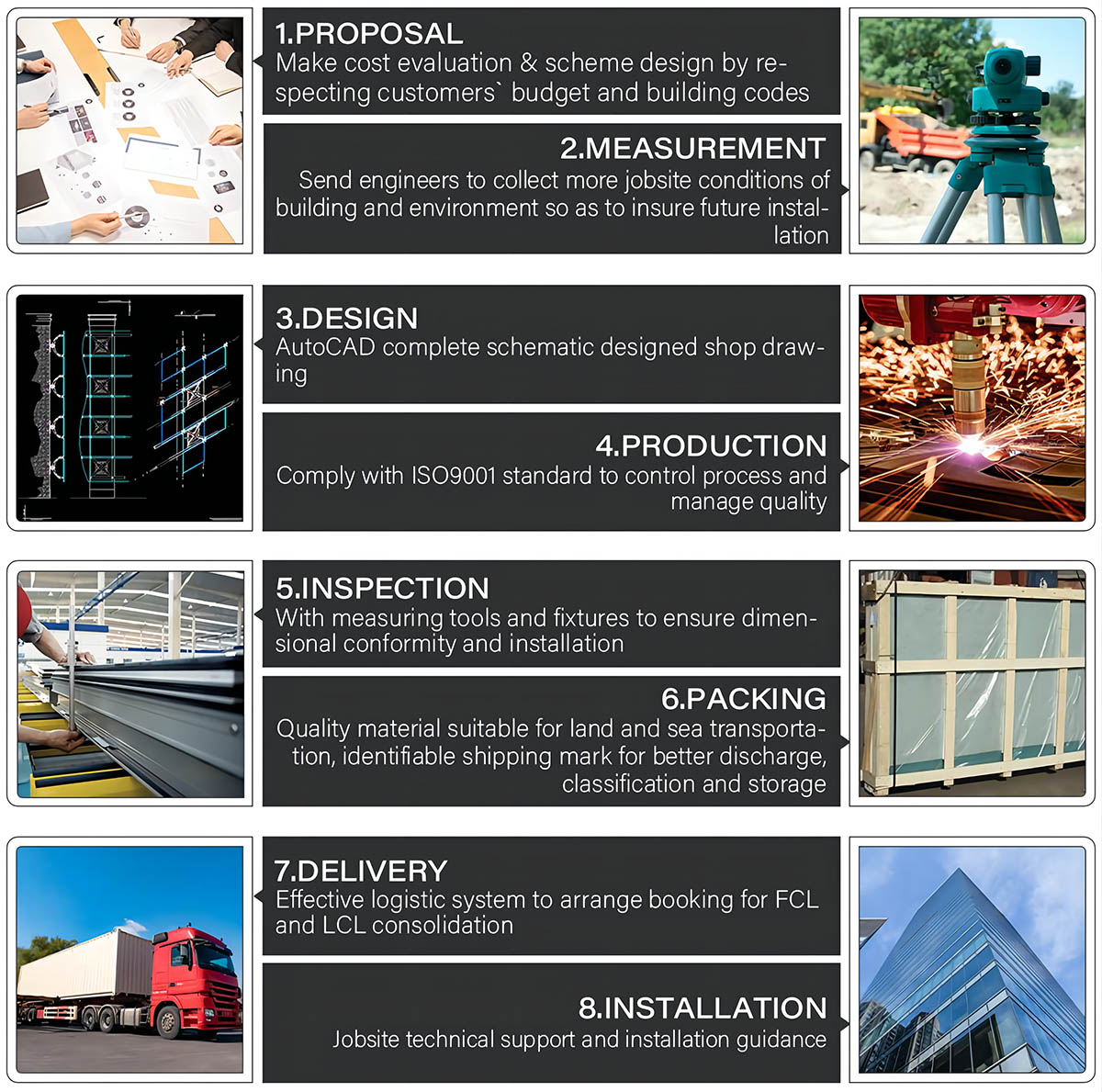

Biyan kuɗi → Shigar da tsarin ƙarfe na sama na sama → Ƙarƙashin firam ɗin ƙasa da gefe → Shigar da gilashi → allurar manne da hatimi → Tsaftace da dubawa

Mabuɗin shigarwa

1. Matsayi

1. Dole ne ma'aunin ma'aunin ma'auni da shimfiɗar bangon labule ya kasance daidai da daidai ko a tsaye tare da babban tsarin ginin, don guje wa sabani tsakanin ginin bangon labule da ginin gida da waje, wanda ke haifar da lahani na Yin da Yang. Angle ba murabba'i bane kuma farfajiyar kayan ado ba ta daidaita ba.

2. Yi amfani da madaidaicin matakin Laser, theodolite, daidaita daidaitaccen tef ɗin ƙarfe, guduma, mai mulki don sake dubawa.Don bangon labule mai tsayi fiye da 7m, ya kamata a auna shi kuma a duba sau biyu don tabbatar da daidaiton bangon labule.Bambancin tsakanin manyan layin tsakiya da na ƙasa dole ne ya zama ƙasa da 1 mm zuwa 2mm.

3. Dole ne a yi watsi da ma'auni lokacin da iska ba ta da girma fiye da karfi 4, kuskure tsakanin ainihin wayoyi da zane zane ya kamata a gyara, rarraba da narkewa, ba zai iya tarawa ba.Yawancin lokaci ana warware shi ta hanyar daidaita nisa na rata da matsayi na firam.Idan kuskuren girman yana da girma, yi tunani a cikin lokaci, kuma sake yin gilashi ko amfani da wani bayani mai ma'ana.

5. Ganuwar labulen gilashin kai tsaye tana gyara gilashin zuwa babban tsarin, da farko billa gilashin zuwa ƙasa, sannan ƙayyade madaidaicin madaidaicin gwargwadon girman gefen waje.

2.Upper karfe tsarin shigarwa

1. Kula da hankali don duba sashin da aka saka ko anchoring karfe farantin karfe yana da ƙarfi, ingancin ƙugiya ya kamata ya zama abin dogara, wurin da aka ɗaure ba ya kamata ya kasance kusa da gefen memba mai ƙarfafawa, diamita da zurfin rijiyoyin burtsatse. ya kamata ya cika ka'idojin fasaha na masana'anta na anka, ya kamata a tsaftace tokar rami.

2. Matsayin shigarwa da tsayin kowane bangare zai ci gaba sosai daidai da buƙatun saka wayoyi da zane-zane.Abu mafi mahimmanci shi ne cewa layin tsakiya na katako mai ɗaukar nauyi dole ne ya kasance daidai da layin tsakiyar bangon labule, kuma tsakiyar rami na elliptical ya kamata ya dace da matsayi na derrick da aka tsara.

3. Na ciki karfe clip shigarwa dole ne santsi da kuma mike.Wajibi ne a yi amfani da layin ja-ta-kashi na yanki don dubawa da daidaita karkacewar da walda ta haifar.Yakamata a hada matsin bakin karfe na waje bisa ga lambar serial, kuma yana buƙatar madaidaiciya.Ya kamata tazara na shirye-shiryen ƙarfe na ciki da na waje ya zama iri ɗaya kuma girman ya dace da buƙatun ƙira.size.

3.Underframe da gefen frame hawa

Gina daidai da wayoyi matsayi da ƙira girma, duk karfe tsarin surface da weld hadin gwiwa goga anti-tsatsa Paint.Tsaftace datti a cikin ƙananan iyaka.Akalla 2 neoprene pads ya kamata a sanya su a kasan kowane yanki na gilashi, kuma tsawon kada ya zama ƙasa da 100mm.

4.Glass shigarwa

Gilashin ɗagawa da sanyawa dole ne a aiwatar da su daidai da tsarin ginin wurin

5.Silicone Sealant allura da tsaftacewa

Gine-ginen kauri na siliki mai jure yanayin yanayi yakamata ya kasance tsakanin 3.5 ~ 4.5mm, madaidaicin haɗin gwiwa na bakin ciki ba shi da kyau ga ingancin rufewa da hana ruwan sama.Bugu da ƙari, allurar manne kada a yi shi a ƙananan zafin jiki na ƙasa da 5 ℃, saboda zafin jiki ya yi ƙasa da ƙasa, manne zai gudana, jinkirta lokacin warkewa, har ma yana shafar ƙarfin ƙarfi.Sanya tef ɗin mannewa tare da matsayin haɗin gwiwa don hana silica gel daga gurbata gilashin.Ƙwararrun aikin alluran roba.Bayan allurar manne, yi amfani da kayan aiki na musamman don goge manne, yana sanya suturar manne ta ɗan ɗanɗana saman.Gilashin gilashi da ƙarfe na ɓangaren allurar manne yakamata a goge su da tsaftar acetone ko wanka na musamman, kar a yi amfani da rigar rigar da ruwa.

Marufi & jigilar kaya

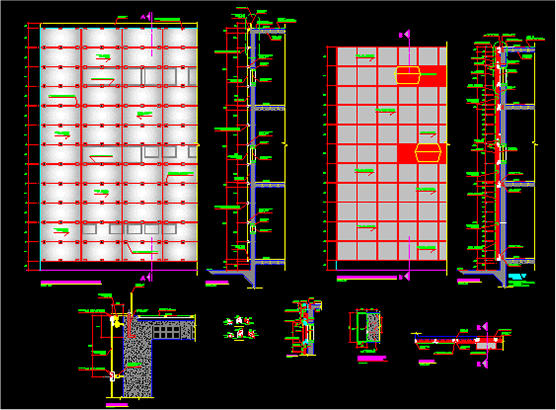

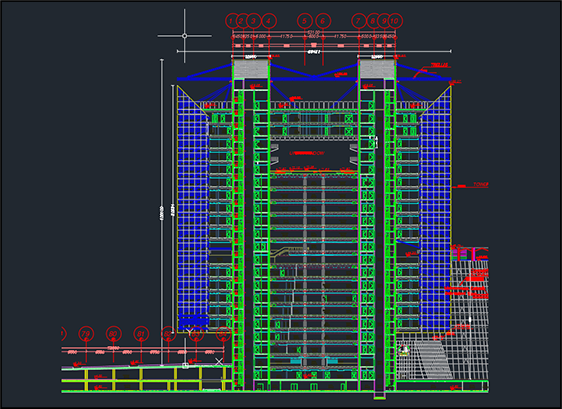

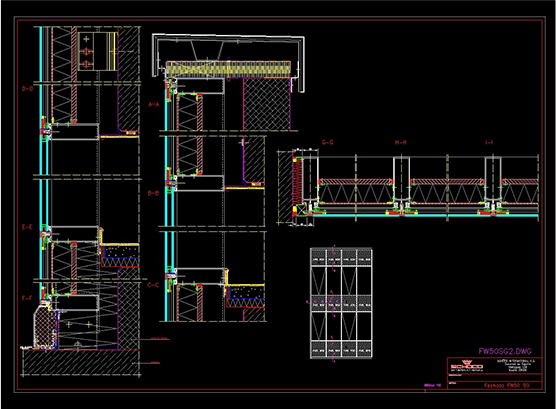

Zane Na Musamman Kyauta

Mun tsara hadaddun gine-ginen masana'antu don abokan ciniki ta amfani da AutoCAD, PKPM, MTS, 3D3S, Tarch, Tekla Structures (Xsteel) da dai sauransu.

Tsarin keɓancewa

Bayanin Bita na Production

Iron Workshop

Raw Material Zone 1

Aluminum alloy workshop

Raw Material Zone 2

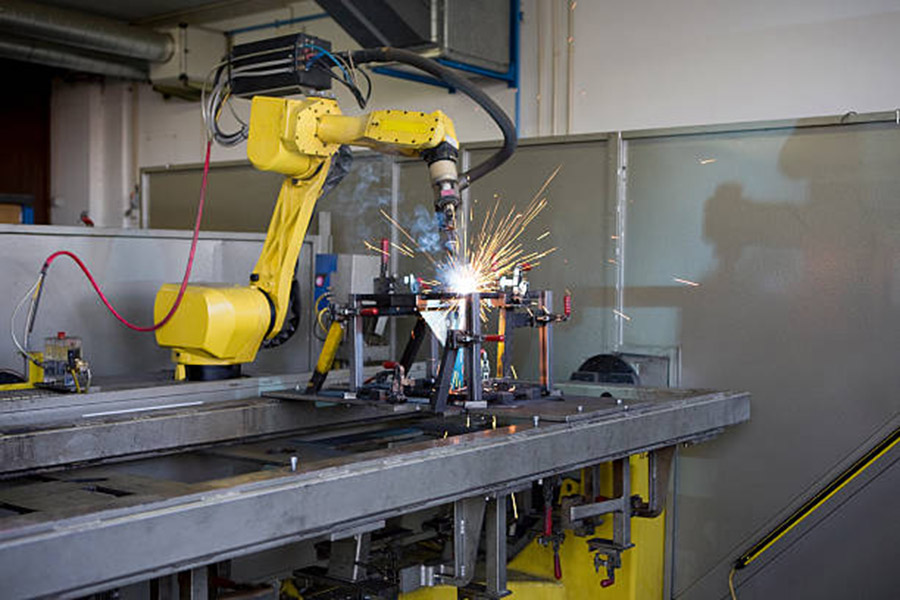

Injin walda na robotic da aka sanya a cikin sabon masana'anta.

Wurin fesa atomatik

Injin yankan da yawa

Hukumar tabbatarwa

fAQ

1.What's your masana'antu lokacin?

Kwanaki 38-45 ya dogara da biyan kuɗin da aka karɓa da kuma sanya hannu kan zanen shagon

2. Menene ya bambanta samfuran ku da sauran masu kaya?

Madaidaicin inganci mai inganci da farashi mai fa'ida sosai gami da tallace-tallacen ƙwararru da sabis na injiniyan shigarwa.

3. Menene tabbacin ingancin da kuka bayar kuma ta yaya kuke sarrafa inganci?

Ƙaddamar da hanya don bincika samfurori a duk matakai na tsarin masana'antu - albarkatun kasa, a cikin kayan aiki, ingantattun kayan ko gwadawa, kayan da aka gama, da dai sauransu.

4. Ta yaya ake samun ingantaccen zance?

Idan za ku iya samar da bayanan aikin masu zuwa, za mu iya ba ku da ingantaccen zance.

Lambar ƙira / ƙirar ƙira

Matsayin ginshiƙi

Matsakaicin saurin iska

Seismic lodi

Matsakaicin gudun dusar ƙanƙara

Matsakaicin ruwan sama

Kamfanin haɗin gwiwa